working principle

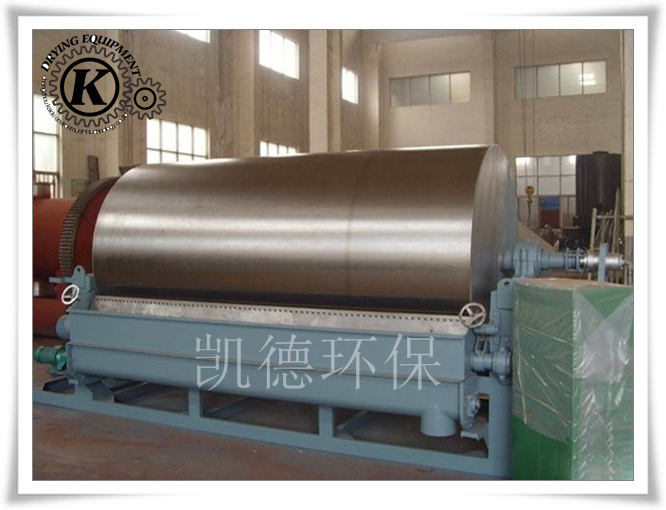

Drum dryer heat conduction within a rotating drying device, the outer wall of the drum in the wet material obtained conductively heat transfer, water removal, to achieve the desired water content of the wet. Heat generated by the inner wall reached the outer tube, and then through the membrane material, high thermal efficiency, continuous operation, it is widely used in liquid or dry material strip material for paste and viscous materials more suitable. & Nbsp; & nbsp; can be divided into two forms: monocular, binoculars dryer. Further operating pressure can also be sub-atmospheric and vacuum forms.

Features and Applications

Operating flexibility, adaptability, able to adapt to a variety of materials and different production requirements.

High thermal efficiency, thermal efficiency which is typically between about 80% -90%.

Drying time is short: the outer wall of the drum dry material wet material film

Drying rate: As thin film material, and the heat and mass transfer consistent with the direction of the film surface can be expected to maintain 30-70kg & middot; H20 (m2 & middot; h) vaporization strength.

Widely used in food, meat, yeast, starch, chemical products, dairy products and so on.

Technical Specifications

| specification | Roller size (mm) |

Effective heating area(m2) | Drying capacity | Steam consumption (Kg/h) |

Motor Power(kw) | Dimensions (mm) |

weight (kg) |

| HG-600 | Ф600×800 | 1.12 | 40-70 | 100-175 | 2.2 | 1700×800×1500 | 850 |

| HG-700 | Ф700×1000 | 1.65 | 60-90 | 150-225 | 3 | 2100×l000×l800 | 1210 |

| HG-800 | Ф800×1200 | 2.26 | 90-130 | 225-325 | 4 | 2500×11OO×l980 | 1700 |

| HG-1000 | Ф1000×1400 | 3.30 | 130-190 | 325-475 | 5.5 | 2700×1300×2250 | 2100 |

| HG-1200 | Ф1200×1500 | 4.24 | 160-250 | 400-625 | 7.5 | 2800×1500×2450 | 2650 |

| HG-1400 | Ф1400×1600 | 5.28 | 210-310 | 525-775 | 11 | 3150×1700×2800 | 3220 |

| HG-1600 | Ф1600×1800 | 6.79 | 270-400 | 675-1000 | 11 | 3350×1900×3150 | 4350 |

| HG-1800 | Ф1800×2000 | 8.48 | 330-500 | 825-1250 | 15 | 3600×2050×3500 | 5100 |

| HG-1800A | Ф1800×2500 | 10.60 | 420-630 | 1050-1575 | 18.5 | 4100×2050×3500 | 6150 |

.jpg)

.jpg)

.jpg)