Outline

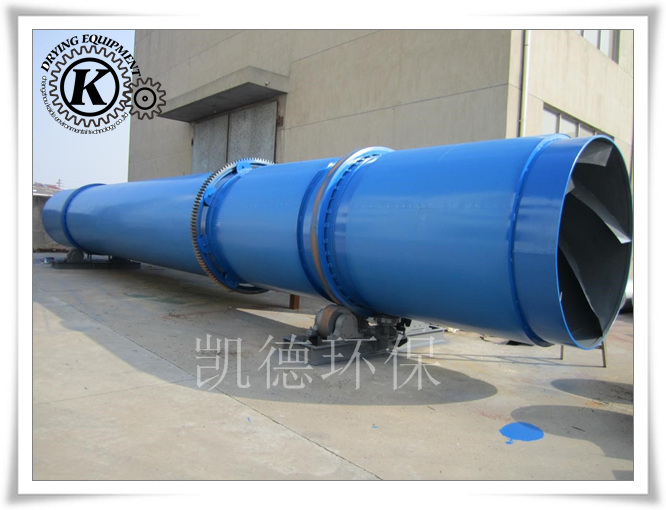

Kiln dryer for hard ferrite calcined powders can also be used in cement, metallurgy, chemical and other industries. Apparatus main kiln and its supporting transmission, cooling, fuel system, electrical control, secondary air intake, exhaust and dust removal device preheater kiln and other components. With over-temperature alarm, overload alarm, automatic temperature control, adjustable features such as kiln oxygen.

Principle

After the wet material into the dryer from one end of the inner cylinder cloth copy board is turning, the material in the dryer uniformly distributed and dispersed, and full contact with and flow (countercurrent) hot air to speed up the drying heat, mass transfer driving force. During the drying process, the material under the action of the copy board and hot air with the inclination, adjustable moved to another section of the dryer exhaust discharge valve star products.

Application

Used in chemical, mining, metallurgy and other industries large particles, drier than the major materials.

Suitable such as: ore, blast furnace slag, coal, metal powder, fertilizer, ammonium phosphate.

Suitable for special requirements powder, dry granular materials. Such as: foaming agent, lees residue, precipitated calcium carbonate, activated clay, magnetic powder, graphite, dregs.

Feature

Low-temperature drying requirements, and the need for large quantities of continuous drying of materials.

Drum drier high degree of mechanization, large production capacity.

Fluid through the barrel resistance, low consumption function.

The material characteristics of strong adaptability.

Stable operation and low operating costs, the dried product uniformity.

Technical Specifications

|

|

Direct heating Downstream |

直接加热 顺流式 |

Direct heating Countercurrent |

Direct heating Countercurrent |

Compound Heat | Compound Heat |

| Type of material | ore | HP foaming agent | Blast furnace slag | Ammonium | Phosphate | coal |

| Capacity(kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| First water content(%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final water content(%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| The average particle size(mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

| Bulk material weight(kg/m3) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| Amount of hot air(kg/h) | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Inlet air temperature(℃) | 600 | 165 | 500 | 180 | 650 | 570 |

| Material outlet temperature(℃) | 42 | 100 | 70 | 80 | 75 | |

| heating method | gas | Electric heating steam | heavy oil | Coal-fired stove | heavy oil | heavy oil |

| Charge coefficient | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Rotating speed(rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Inclination | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Copy number plate | 12 | 24 | 12 | 22 | Inner and outer tube8 The outer cylinder surface16 |

6 12 |

| The diameter of the dryer(m) | 2.0 | 1.5 | 2 | 2.3 | The outer cylinder2 Inner tube0.84 |

The outer cylinder2.4 Inner tube0.94 |

| Dryer length(m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving power(kw) | 22 | 7.5 | 15 | 11 | 11 | 15 |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)