Working Principle

Wet material continuously fed from the feeder on the upper portion of the first layer of drying plate dryer, rake leaves witha rake arm rotary movement so continuously rake leaves turn copied material. Index material along the spiral flow through the disk surface drying, the material was dried in a small disk is transferred to the outer edge and the outer edge of the disk falls below the outer edge of the large drying, drying on a large plate material moved inward and drop from the middle discharge port falls under a layer of small drying pan. Size drying plates are arranged alternately, the material can be continuous through the whole dryer. Heating medium through the hollow of the dry plate, heating medium in the form of saturated steam, hot water or thermal oil heating medium enters from one end of the dry plate exported from the other end. Dried materials fell on the bottom of the housing from the last layer of drying plate, the last being transferred to rake leaves out of the discharge port. The moisture escaping from the material discharged from the humidity on the top cover of the mouth, a vacuum-type plate dryer moisture on the top cover of the pump out of the mouth. Discharged from the bottom of the dry materials can be packed directly. By finned heater with addition, solvent recovery condensers, baghouse, dry material backmixing agencies, induced draft fan and other auxiliary equipment, can increase its drying capacity, dried paste and heat sensitive materials can be easily recycled The solvent and capable of heat decomposition and reaction. & Nbsp;

Disc dryer main application areas

ried pyrolysis calcination reaction was cooled sublimation

(A) organic chemical products

Polyvinyl chloride resin, polytetrafluoroethylene resin, fumaric acid, anthraquinone, nitro anthraquinone, p-aminophenol, melamine, cyanuric acid, sulfanilic acid, Antioxidant 168, naphthol As, hard aliphatic acid salts, aniline, nitroaniline, dipentaerythritol, chlorinated paraffin, calcium formate, triethylenediamine, sodium benzene sulfinate, isophthalic acid, dimethyl five sulfonate, thiourea, oil-soluble aniline black dye, acid black dyes and other organic chemical raw materials and intermediates.

(B) inorganic chemical products

Precipitated calcium carbonate, calcium carbonate, nano-scale ultra-fine calcium carbonate, magnesium carbonate, aluminum hydroxide, white and gray, strontium carbonate, barium carbonate, potassium carbonate, lithopone, insurance powder, barium sulfate, potassium sulfate, microspheres catalysts, magnesium hydroxide, copper sulfate, nickel sulfate, nickel amine acid, sodium molybdate, sodium chloride, cryolite, red iron oxide, lithium hydroxide, nickel hydroxide, zirconium hydroxide, calcium phosphate, sulfur and so on.

(2) medicine, food

Ampicillin toxins, Deng salt, L-phenylglycine and intermediates, cefotaxime, ceftriaxone, dipyrone, cimetidine, vitamin B12, vitamin C, a pharmaceutically acceptable salt, pharmaceutical aluminum hydroxide, medicinal bias magnesium silicate, caffeine, tea, flower extract, ginkgo leaf, chocolate powder, starch, corn germ and other raw materials and pharmaceutical intermediates.

(3) feed, fertilizer

Potassium carbonate, bio-fertilizer, protein feed, feed chlortetracycline, mycelia, wheat bran, distiller's grain, food, seed, herbicides, cellulose, calcium hydrogen phosphate and other feed. & Nbsp;

Disc dryer using Features

(1) regulation of easy applicability

1, adjust the thickness of material, spindle speed, number of rake arm, rake leaves type and size allows the drying process to achieve the best.

2, each drying plate can be fed separately hot medium or cold medium, the material for heating or cooling, the material temperature control is accurate and easy.

3, the residence time of the material can be accurately adjusted.

4, a single flow of materials, no back-mixing, even drying and stable quality, without mixing.

(2) the operation is simple, easy

1, dryer car parking operation is very simple.

2, stop feeding, rake leaves transferred material can be easily discharged out of the dryer.

3, through large-scale viewing doors and mirrors, can be carried out within the equipment very carefully cleaning and observation.

(3) low energy consumption

1, the material layer is thin, low spindle speed, material delivery system needs small power, less power consumption.

2, by conducting heat drying, high thermal efficiency, low energy consumption.

(4) operating environment, recyclable solvents, dust emissions to meet the requirements

1, atmospheric type: Due to the low flow rate in the device, and the humidity inside the equipment distribution compete with low dust is difficult to float to the top of the device, so the top of the exhausts from the outlet of the exhaust gas contains almost no dust.

2, closed-type: with solvent recovery device, can be easily recycled wet gas contained in the organic solvent. Solvent recovery is simple, high recovery rate for flammable, explosive, toxic and easy oxidation of materials that can be used wet nitrogen as the carrier gas in closed loop to make it safe to operate. Especially suitable for flammable, explosive, toxic materials drying.

3, vacuum-type: disc dryer is operating under vacuum state, especially suitable for drying heat sensitive materials.

(5) Easy installation, small footprint

1, dryers overall factory, the overall transport, simply hoisting, positioning is very easy to install.

2, since the drying plates being arranged by layers and installed vertically, even drying area is large, the area is also very small.

Technical characteristics

(1) drying trays

1, the design pressure: generally 0.4MPa, up to 1.6MPa.

2, the maximum working pressure: Usually & le; 0.4 MPa, up to 1.6 MPa.

3, the heating medium: steam, hot water, thermal oil, drying plate temperature & le; 100 ℃ when heated with hot water, 100 ℃ ~ 150 ℃ time by & le; 0.4 MPa saturated steam or superheated steam heating, 150 ℃ ~ 320 ℃ when using oil heating, & gt; can be electric, lead oil generation, molten salt, etc. 320 ℃ when heated.

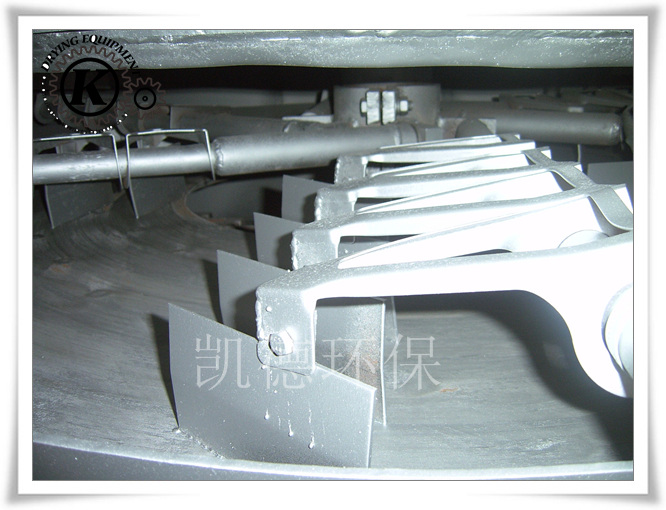

(2) the material transport system

1, spindle speed: 1 to 10 rev / min, variable speed motor or inverter.

2, rake arm: 2 to 8 is fixed on the spindle rake arm on each drying trays.

3, rake leaves: hinged rake arm can float to remain in contact with the surface of the plate, there are a variety of types.

4, Roller: easily broken and needs caking material in place by placing roller can be enhanced heat transfer and drying process.

(3) housing

There is pressure, sealed, vacuum three types

1, atmospheric type: original cartridge or octagonal column, there is a whole and split two structures. Heating medium can import and export the main channel in the housing and to be in housing.

2, closed type: cylindrical casing, 5Kpa withstand internal pressure, the heating medium may be the main conduit and export in the housing, it may be external to the housing.

3, vacuum type: cylindrical housing, the design pressure of external pressure 0.1MPa, the heating medium in charge of import and export channel within the housing.

Technical Specifications

| specification | An outer diameter(mm) | height (mm) |

Drying area (m2) |

power(kW) | specification | An outer diameter(mm) | height(mm) | Drying area(m2) | power(kW) |

| 1200/4 | 1850 | 2608 | 3.3 | 1.1 | 2200/18 | 2900 | 5782 | 55.4 | 5.5 |

| 1200/6 | 3028 | 4.9 | 2200/20 | 6202 | 61.6 | ||||

| 1200/8 | 3448 | 6.6 | 1.5 | 2200/22 | 6622 | 67.7 | 7.5 | ||

| 1200/10 | 3868 | 8.2 | 2200/24 | 7042 | 73.9 | ||||

| 1200/12 | 4288 | 9.9 | 2200/26 | 7462 | 80.0 | ||||

| 1500/6 | 2100 | 3022 | 8.0 | 2.2 | 3000/8 | 3800 | 4050 | 48 | 11 |

| 1500/8 | 3442 | 10.7 | 3000/10 | 4650 | 60 | ||||

| 1500/10 | 3862 | 13.4 | 3000/12 | 5250 | 72 | ||||

| 1500/12 | 4282 | 16.1 | 3.0 | 3000/14 | 5850 | 84 | |||

| 1500/14 | 4702 | 18.8 | 3000/16 | 6450 | 96 | ||||

| 1500/16 | 5122 | 21.5 | 3000/18 | 7050 | 108 | 13 | |||

| 2200/6 | 2900 | 3262 | 18.5 | 3.0 | 3000/20 | 7650 | 120 | ||

| 2200/8 | 3682 | 24.6 | 3000/22 | 8250 | 132 | ||||

| 2200/10 | 4102 | 30.8 | 3000/24 | 8850 | 144 | ||||

| 2200/12 | 4522 | 36.9 | 4.0 | 3000/26 | 9450 | 156 | 15 | ||

| 2200/14 | 4942 | 43.1 | 3000/28 | 10050 | 168 | ||||

| 2200/16 | 5362 | 49.3 | 5.5 | 3000/30 | 10650 | 180 |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)